Product Description

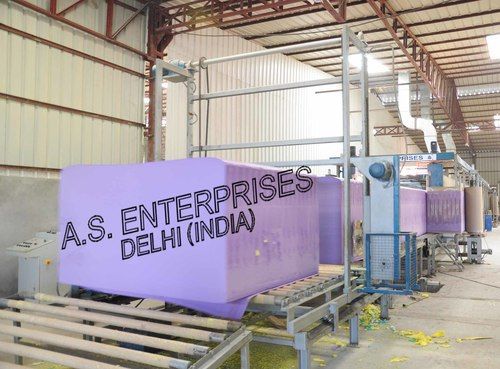

We are the manufacturer and suppliers of the best quality of PU Foam Plant. We are also exporter of Foam Plant.

Specification

|

Condition

|

New

|

|

Model

|

FM400

|

|

Space Required

|

50 m x 6 m

|

|

Power Required

|

90 kW

|

|

Power Supply

|

410 v Ac 50hz

|

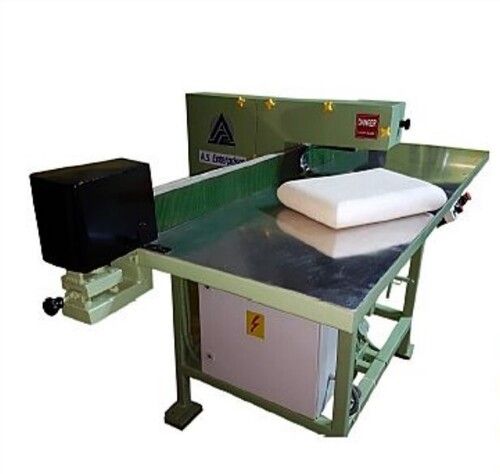

Outstanding Performance and BuildThe foam plant features a robust steel construction and an automatic electric drive, ensuring long-lasting durability and smooth operation. Its high torque design supports demanding cutting processes, while the low noise output preserves comfort in your workspace. This powerful combination results in reliable daily performance for any foam manufacturing environment.

Efficiency and Quality You Can TrustEngineered for maximum efficiency, this foam plant streamlines the manufacturing workflow and reduces operational costs. Its high-quality output and consistent results help businesses maintain the standards their clients expect. Automatic control further minimizes manual input for a smooth, reliable production line.

FAQs of Foam Plant:

Q: How does the electric drive system enhance foam plant performance?

A: The electric drive system in our foam plant delivers strong torque, resulting in precise and efficient foam cutting. It boosts productivity by minimizing mechanical losses and delivers a quieter working environment.

Q: What applications is this foam plant suited for?

A: This machine is primarily used for cutting and making foam products, catering to various industries such as furniture, bedding, and packaging that require consistent and high-quality foam output.

Q: Where is this foam plant manufactured and supplied from?

A: Our foam plant is designed, manufactured, and supplied directly from India, serving clients nationwide and supporting export demands as well.

Q: When should I consider using this foam plant for my business?

A: You should use this foam plant when your production requires automatic, efficient, and high-quality foam cutting with minimal manual intervention and low noise operation.

Q: What is the process for operating the plant without computerized controls?

A: Despite not being computerized, the machines automatic functions make it user-friendly. Operators can start the machine, set the desired parameters, and monitor the process with minimal effort, ensuring smooth foam production.

Q: What benefits do users gain from this foam plants features?

A: Users benefit from its high efficiency, excellent cutting precision, low operational noise, strong durability, and reduced manual laborwhich collectively enhance overall productivity and product quality.