Product Description

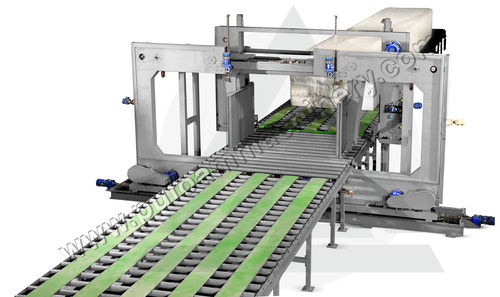

Leveraging on our state-of-the-art infrastructural unit, we have been a proud manufacturer of Circular Foam Cutting Machine for our widely scattered clients. It is precisely for providing an accurate and reliable means of cutting flexible PU foam blocks into required thickness ranging from mattresses (100 to 200 mm) to thin sheets as low as 1.5 mm. Circular Foam Cutting Machine is fully automatic and is available in two sizes CCM56 & CCM66. The cutting executed by an endless band saw blade running on four dynamically balanced wheels provide a smooth and finished cut.

Standard Equipment:

- Rotary slitting table with wooden tabletop having friction surface.

- Circumference friction drive (max. Speed 100m/min) having soft movement on table-start and -stop.

- Infinitely variable table speed control : 0 to 5 rpm using a variable frequency drive.

- Slitting section with four balanced blade-wheels.

- Motorized slitting section. lift/lower mechanism.

- Tensioned PTFE coated blade guide.

- Electric blade drive motor.

- Single-edge ground band-knife with manual tensioning system Band-knife width: 30 mm.

- Electric grinding apparatus with two adjustable cup-stones. (Manual dresser).

- Grinding dust exhaust.

- Vacuum system in slitting area.

- Electric adjustment of slitting angle: 0 to 5 degrees.

- Control panel with PLC & colour touch screen.

- Pre-selection of slitting thickness by touch screen from 1.5 mm to 200 mm.

- Pre-selection of number of table-revolutions through touch screen for 1-999.

Technical Specifications Of Circular Foam Cutting Machine:

|

MODEL

|

LOADING CAPACITY

|

SPACE

|

OUTER TABLE DIAMETER

|

INNER DIAMETER

|

|

6 ft. x 3ft.

|

2m x 1m

|

2m x 1.5m

|

|

CCM40-B

|

4

|

3

|

-

|

5m x 5m

|

4m

|

1 m

|

|

CCM56-B

|

8

|

5

|

4

|

7m x 7m

|

5.6m

|

1 m

|

|

CCM66-B

|

11

|

7

|

5

|

7m x 7m

|

6.6m

|

2 m

|

Efficient Automatic Foam Block CuttingDesigned for seamless, automatic operations, this foam cutting machine streamlines your production process. It ensures precision and speed, handling up to 11 kg of foam blocks per hour. The electric drive further optimizes efficiency and reduces manual labor, making it perfect for high-volume manufacturing settings.

Superior Build and Export QualityAs an exporter, manufacturer, and supplier from India, we use stringent quality measures and robust materials to produce machines that meet international standards. Our circular cutting mechanism ensures smooth, reliable cuts for consistent product output, enabling businesses worldwide to trust our equipment for their foam cutting requirements.

FAQs of Circular Foam Cutting Machine:

Q: How does the automatic circular foam cutting machine operate?

A: The machine runs on an electric drive and automates the process of cutting foam blocks. Simply load the foam onto the cutting bed, set the block dimensions, and activate the machine; it then performs precise, consistent cuts automatically.

Q: What type of foam can this machine cut and what is its capacity?

A: This machine is suitable for general-purpose foam block cutting and can handle up to 11 kg of foam blocks per hour, making it efficient for medium- to large-scale operations.

Q: When is computerized control required for foam cutting, and is it available on this model?

A: Computerized controls are generally preferred for highly complex or customizable cuts. This model is not computerized, focusing instead on reliable, automatic operation for standard foam block shapes, maximizing simplicity and durability.

Q: Where is this foam cutting machine manufactured and supplied from?

A: Our foam cutting machines are manufactured, exported, and supplied from India, offering high-quality machinery to clients both domestically and internationally.

Q: What is the typical process for cutting foam blocks using this machine?

A: The process involves placing the foam block on the cutting table, configuring the necessary specifications, and allowing the automatic, electric-powered system to handle the rest, ensuring uniform and efficient cuts.

Q: How can this machine benefit my production line?

A: By automating the foam cutting process, you achieve higher throughput, reduced material waste, consistent output quality, and lower labor requirements, enhancing the overall efficiency of your production line.