Product Description

Batch Foaming Machine is one of the most popular machine for which we are considered an acclaimed manufacturer in the market. It is used to produce flexible PU foam blocks with one block at a time process. It is meant for relatively low production capacity upto 30 to 40 blocks per 8 hour Density 10 to 32. Batch Foaming Machine is hence demanded by our clients in global markets. Clients can avail this machine from us at highly reasonable prices.

Specifications Of Batch Foaming Machine:

|

GENERAL SPECIFICATION

|

MODEL BFM B

|

|

Mixer motor

|

10 H.P. with AC drive for speed control.

|

|

Mixing tank

|

210 Liters

|

|

MIXING CAPACITY

|

125 KG

|

|

Material discharge

|

From bottom by manually operated lifting mechanism.

|

|

Control Panel

|

One mould of 6ft. x 9ft. having aluminium sheets on sides & wooden board on the base.

|

|

Space required

|

4m x 8m

|

|

Power required

|

10 HP

|

|

Power required

|

415V AC 50Hz

|

Process Of Batch Foaming Machine:

First, all chemicals are weighed & kept ready for the process.Polyol and catalysts are poured into the mixing vessel and first mixing is started by pressing the speed 1 push button.

Now TDI & Water are poured in quick succession & Speed 2 is switched ON. The machine mixes the chemicals & releases them into the mold. The open door in the mold is closed manually. The block may be demolded after 5 to 10 minutes.

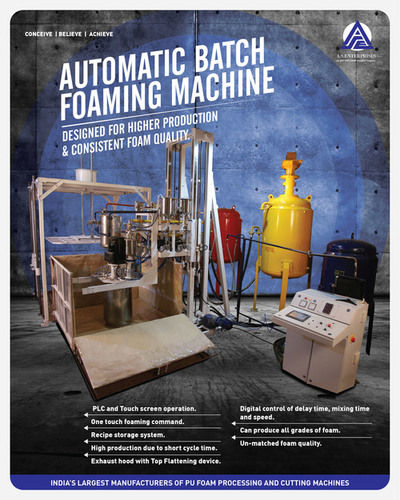

Advanced Automatic Foaming TechnologyExperience seamless foam production with this fully automatic batch foaming machine. Its computerized controls ensure precise measurements and uniform output, making it suitable for large-scale manufacturing applications.

Robust Construction for Industrial UseBuilt from mild steel and finished in a stylish grey, the machine is engineered for durability and long-term use. Its design accommodates demanding operational environments typically found in modern factories.

FAQs of Batch Foaming Machine:

Q: How does the Batch Foaming Machine operate without PLC control?

A: The Batch Foaming Machine utilizes advanced computerized technology to manage and automate the foaming process. Even without PLC control, the systems integrated controls provide accurate operation and efficient production cycles.

Q: What materials and capacity can this foaming machine handle?

A: Constructed from durable mild steel (MS), the machine can process between 6/6 and 6/9 kilograms of foam per hour, making it suitable for medium to high-volume manufacturing requirements.

Q: When is this machine typically used in manufacturing?

A: This machine is ideal for use during initial production phases in industries that require consistent and high-quality foam, such as bedding, furniture, and packaging sectors.

Q: Where is the Batch Foaming Machine manufactured and supplied from?

A: The machine is manufactured and supplied from India, catering to both domestic and international buyers as an exporter, manufacturer, and supplier.

Q: What is the process for producing foam using this machine?

A: Operators load raw materials and select programmable recipes via the computerized interface. The machine automatically mixes, reacts, and forms foam batches with minimal manual oversight.

Q: How does the computerized system enhance machine usage?

A: The computerized controls streamline operation by ensuring accurate ingredient dispensing and timing, which boosts efficiency and reduces the chances of human error during foam production.

Q: What are the key benefits of choosing this foaming machine?

A: The benefits include automated, accurate foam production, robust MS construction, 1-year warranty, and the backing of a reputable Indian exporter, making it a smart investment for industrial manufacturers.