Product Description

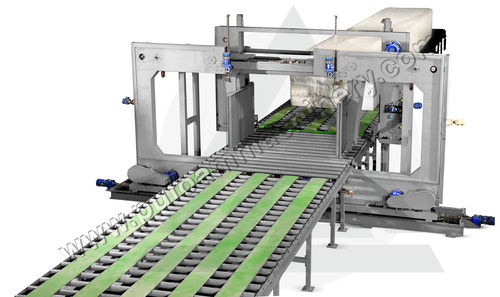

Automatic Circular Foam Cutter consumes the total voltage that ranges from 110 to 220V and the rated power is around 1000W. If we talk about the dimensions of the machine then it is3600*2270*1100mm and the weight is noted down to be 200KG. The product is CE certified and is reliable for high performance. The durability of the product is ensured by its rust proof feature and structure which is robust and sturdy. The capacity of production and also the color can be customized as per the requirement of our buyers. Automatic Circular Foam Cutter offers the cutting speed of 0-6000mm/min.

KEY POINTS:-

- Product has the cutting size that varies as per the need of the customer. Like 1313 1325 1530

- The machine is well incorporated with high capacity of motor that can easily take heavy loads.

- The thickness of cutting is solely dependent on plasma source and the need.

- It is widely demanded in various sectors and areas such as hotels, Energy & Mining, Machinery Repair Shops, Manufacturing 5) Plant,Construction works, Food & Beverage Factory, Farms, Restaurant, Home Use, Printing Shops, Retail, Food Shop, etc.

Specification

|

Condition

|

New

|

|

Loading Capacity

|

11 -6 Ft. X 3ft., 7- 2m X 1m , 5-2m X 1.5m

|

|

Ranging from Mattresses

|

100 to 200 mm

|

|

Power Supply

|

415 V AC 50

|

|

Stacking Height

|

1200 mm

|

|

Power Required

|

22 HP , "220v/60z Electricals be provided against order

|

|

Space

|

7m X 7m

|

|

Outer Table Diameter

|

6.6m

|

|

Inner Diameter

|

2 M

|

|

Infinitely Variable Table Speed Control

|

0 to 3 rpm using a variable frequency drive.

|

|

Manual Adjustment of Slitting Angle

|

0 to 5 degrees.

|

|

Pre Selection of Slitting Thickness

|

3 mm to 200 mm.

|

Efficient Foam Cutting OperationsThe Automatic Circular Foam Cutting Machine is tailored for industrial use, offering rapid and uniform foam cutting capabilities. Its automatic drive streamlines production, reducing manpower and minimizing operational errors. Crafted from high-grade steel, it is built for longevity and reliable function in demanding environments.

User-Friendly Automatic FunctionalityEase of use defines this machine, thanks to its fully automatic operation. Without the need for computerized controls, it ensures straightforward management while maintaining accuracy and speed. The electric drive type ensures consistent performance, making it suitable for continuous industrial activities.

FAQs of Automatic Circular Foam Cutting Machine:

Q: How does the Automatic Circular Foam Cutting Machine operate?

A: The machine uses an electric drive at 50 Volts and operates automatically, allowing users to cut foam circularly without manual intervention. Simply set up the foam, turn on the machine, and let it handle the cutting process efficiently.

Q: What materials can be cut using this machine?

A: This foam cutting machine is specifically designed to cut various types of industrial foam with precision. Its steel build ensures steady handling of heavy-duty and bulk foam materials.

Q: Where is this machine commonly used?

A: It is widely employed in industrial settings such as furniture manufacturing, insulation products, automotive, and packaging industries, primarily in locations where mass foam cutting is essential.

Q: When should I choose an automatic, non-computerized machine like this one?

A: This machine is ideal if you require dependable, large-scale foam cutting without complex programmable controls. It is suitable for businesses valuing simplicity combined with automation and reliable output.

Q: What is the process of cutting foam with this machine?

A: Place the foam on the machines platform, adjust the settings according to the desired size, power on the electric drive, and the automatic mechanism will precisely cut the foam into circular shapes.

Q: What are the benefits of using this Automatic Circular Foam Cutting Machine?

A: Key advantages include consistent cutting quality, reduced labor requirements, high durability due to steel construction, and reliable performance supported by automatic operation.

Q: Is this product available for export, and can it be supplied across India?

A: Yes, as an established manufacturer, supplier, and exporter based in India, we supply and export these machines to clients nationwide and internationally.